If you’ve ever searched “engine rebuild parts,” you already know how overwhelming it gets — fast. Everyone has a list. Everyone has a favorite brand. Everyone swears this camshaft or that cylinder head is the secret.

But here’s the truth most people don’t hear early enough:

There is no universal “right parts list” for an engine rebuild.

The right parts depend on what the engine is being asked to do, how long it needs to live, and how honest you’re willing to be about your goals and your budget. That’s where most rebuilds go sideways — not because the parts were bad, but because they didn’t match the application.

At Prestige Motorsports, rebuilds don’t start with parts. They start with questions.

What “Engine Rebuild” Really Means

To some people, an engine rebuild means freshening a worn motor and getting it back on the road. To others, it means making more power. To others still, it’s a chance to fix mistakes made the last time around.

Those are very different starting points — and they lead to very different parts choices.

Before any components are selected, professional builders want to know:

- How will the engine be used?

- How much power is actually needed?

- How important are street manners, longevity, and reliability?

- Is this a one-time build, or part of a long-term plan?

Without those answers, parts selection becomes guesswork.

Start With the Goal, Not the Parts

One of the most common mistakes people make is choosing parts based on peak horsepower numbers instead of real-world use.

A street-driven engine doesn’t live at 7,500 RPM.

A road race engine doesn’t care about stoplight torque.

A drag engine doesn’t need to idle politely.

Each application demands a different approach.

That’s why reputable builders don’t sell parts in isolation. They build systems — combinations where every component supports the others.

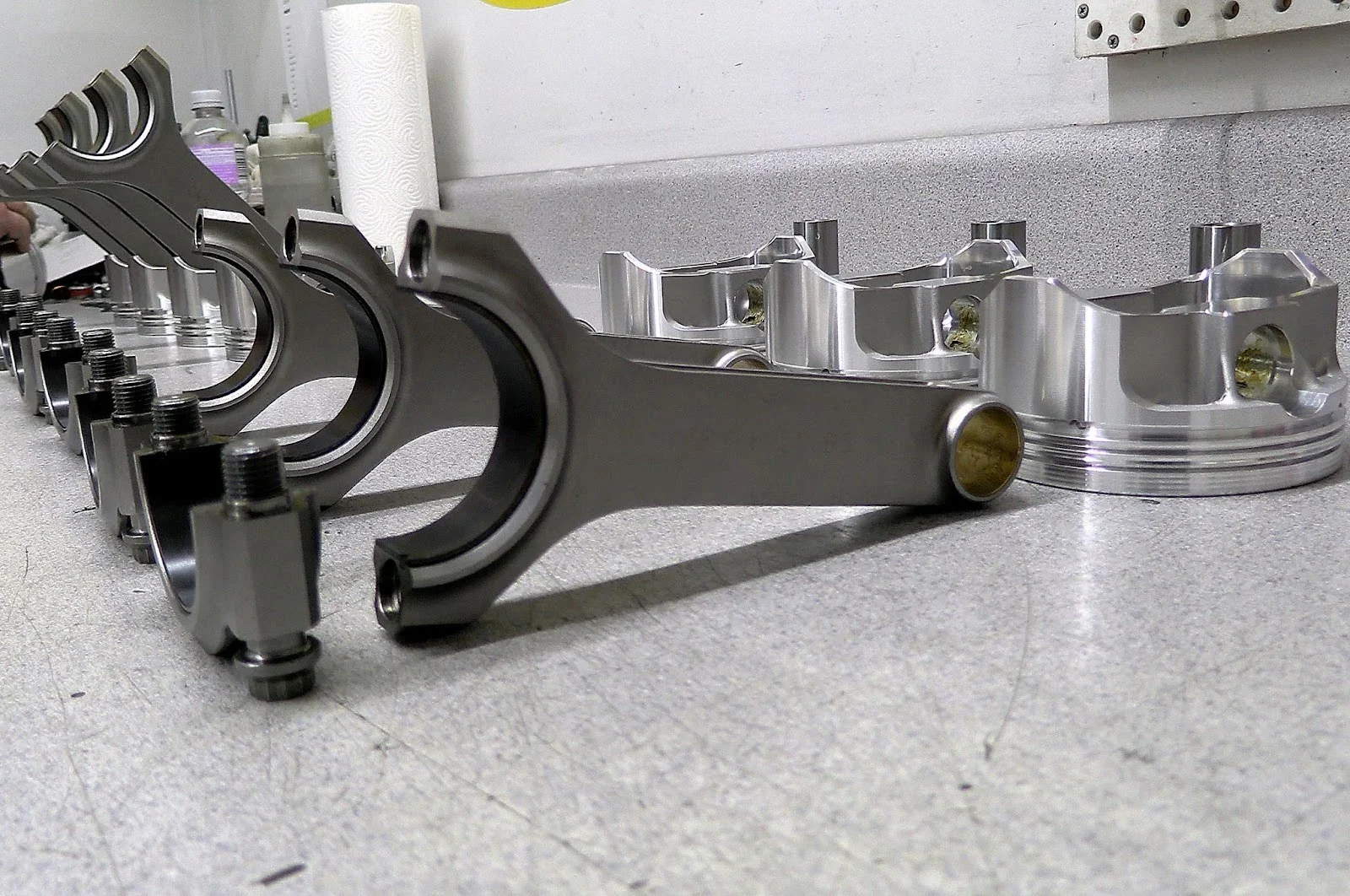

The Components That Matter Most

Not all engine parts carry the same weight. Some choices matter more than others — and a few mistakes can undo an otherwise solid build.

Valvetrain: Where Good Builds Live or Die

The camshaft gets the attention, but it never works alone.

Rocker arms and valve springs must be selected to match:

- Cam profile

- RPM range

- Cylinder head flow

- Intended use

Mismatched valvetrain components are one of the most common causes of premature failure. Too much spring for the application creates unnecessary wear. Too little spring leads to valve float and catastrophic damage.

The goal isn’t aggressive — it’s appropriate.

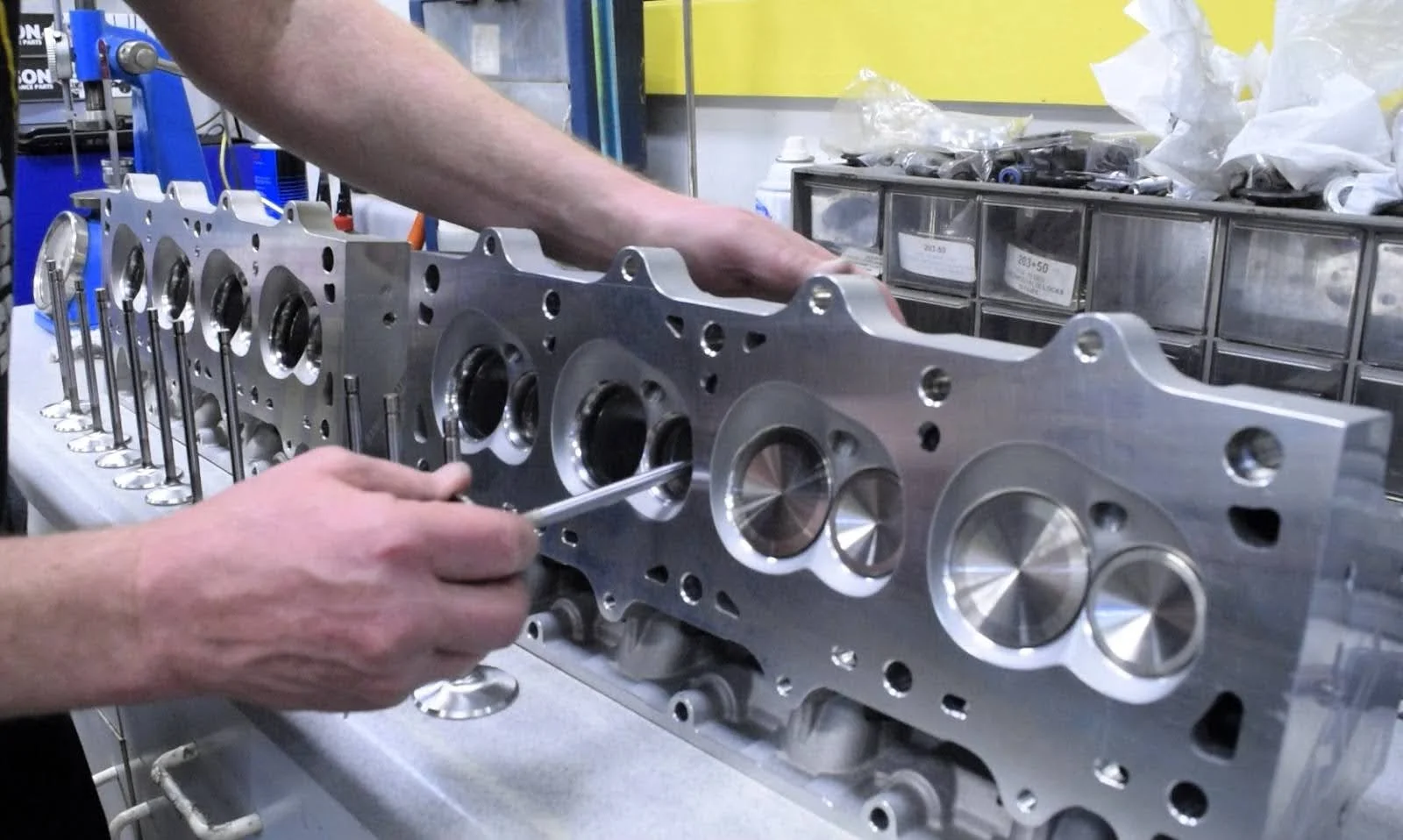

Cylinder Heads: Flow With Purpose

Cylinder heads can make or break a rebuild.

CNC-ported heads, valve size, chamber design — each decision affects:

- Power delivery

- Compression tolerance

- Street drivability

- Cooling efficiency

More airflow isn’t always better if the rest of the engine can’t support it. A balanced head choice often outperforms a “bigger” one that doesn’t match the build.

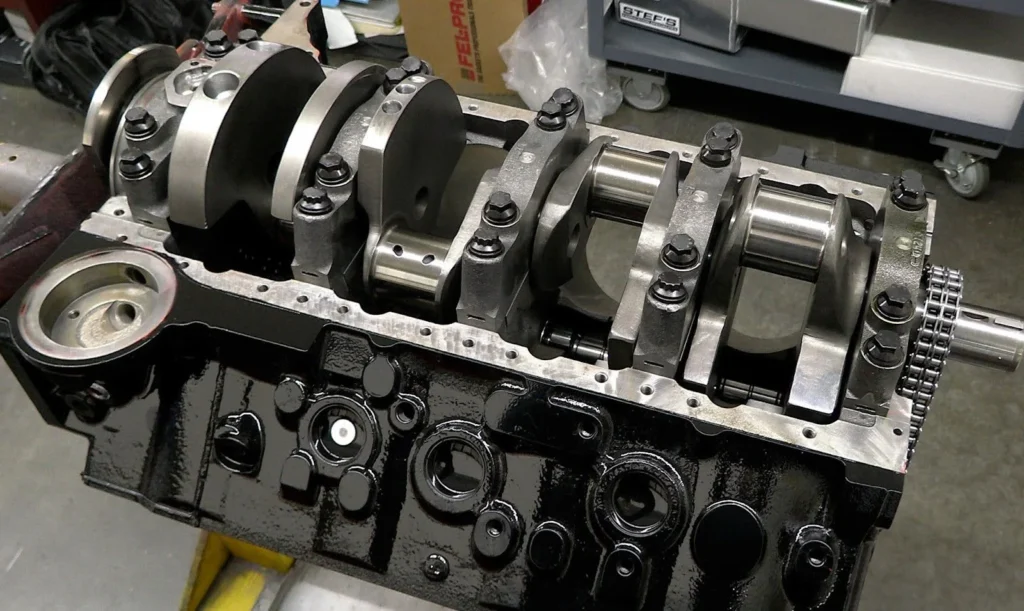

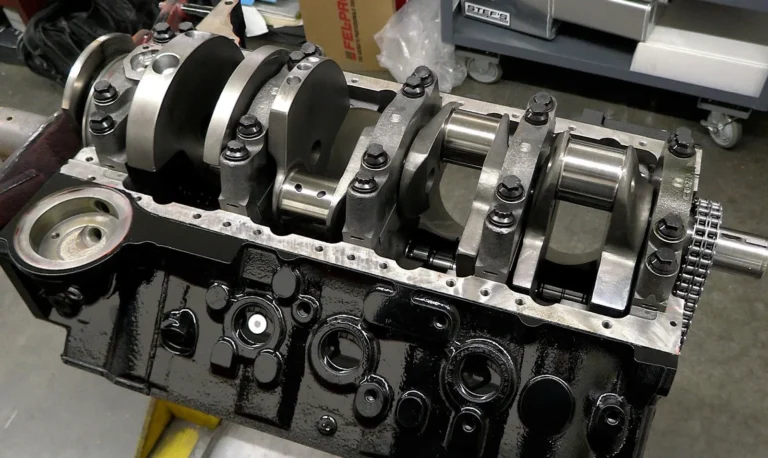

The Block: Know Its Limits

OEM blocks have real limits — and pretending they don’t is expensive.

Once power goals rise beyond a certain point, aftermarket blocks become less of an upgrade and more of an insurance policy. A rebuild should never push a foundation beyond what it can reliably handle.

Longevity comes from respecting those limits, not ignoring them.

Supporting Systems People Underestimate

Many rebuilds fail outside the engine.

Power increases expose weaknesses in:

- Fuel delivery

- Cooling systems

- Oil control

- Transmissions and driveline components

A rebuilt engine that outpaces its support systems will feel great — briefly.

This is why professional builders often recommend upgrades that customers didn’t initially budget for. It’s not upselling. It’s prevention.

A properly matched cooling system, oil pan, and fuel setup protect the investment you’re already making in the engine.

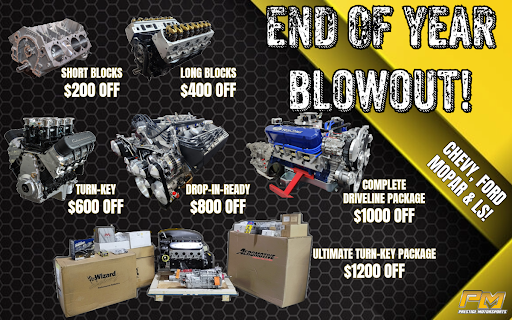

Budget Reality: What an Engine Rebuild Really Costs

One of the first questions people ask is also the hardest one to answer:

“How much does an engine rebuild cost?”

The honest answer is that it depends — not as a dodge, but because rebuild costs are driven by scope, not just parts.

At Prestige, we are very selective about the rebuilds we take on and keep the minimum labor cost (typically $5,000) in mind before parts are even ordered.

For common platforms, rebuild costs creep up because:

- machine work adds time and labor

- worn components need replacing

- hidden damage gets uncovered mid-process

- older supporting systems rarely survive higher output

It’s why a 350 rebuild often ends up close to — or beyond — the price of a brand-new 383 that already includes updated internals. The same applies to 302 and 351W platforms. Rebuilds also pause when machine shops uncover surprises, whereas a 383 is built clean, consistent, and ready to run.

A basic refresh that reuses major components will look very different from a performance rebuild that includes upgraded cylinder heads, valvetrain components, and supporting systems. Labor, machine work, parts quality, and intended use all play a role.

What often surprises people is that the engine itself isn’t always the biggest variable.

As power increases, supporting components start to matter just as much:

- Fuel systems

- Cooling systems

- Oil control

- Valvetrain durability

- Drivetrain compatibility

Skipping those upgrades can reduce upfront cost — but it often increases long-term expense through repeat labor, failures, or limited reliability.

That’s why professional builders don’t quote rebuilds by cubic inches alone. They build around goals, usage, and longevity, then recommend parts that make sense within that reality.

A rebuild done right isn’t about finding the cheapest path forward — it’s about choosing components that won’t force you to do it twice.

Why Professional Planning Matters

A parts-list rebuild assumes everything will work together.

A professionally planned rebuild proves it will.

That difference shows up in:

- Component compatibility

- Dyno validation

- Flat, usable torque curves

- Long-term reliability

Anyone can order parts. Fewer people know how to make them work together.

The Smart First Step

If you’re considering an engine rebuild, the smartest move isn’t buying parts — it’s getting clarity.

Define the goal. Define the use. Define the expectation.

From there, the right parts become obvious — not because they’re trendy, but because they fit the job.

At Prestige Motorsports, rebuilds are planned the same way engines are built: intentionally, honestly, and with the end result in mind.

Because the right parts aren’t the most expensive ones. They’re the ones that let the engine do exactly what it was built to do — every time you turn the key.

To learn more about our engine rebuilding service, reach out to us today.