Building a Custom Car from Scratch: Cost, Time, and Process

When someone says they want to build a car from scratch, we always ask the same question first: “Do you know what that really means?”

Because it sounds simple enough. You start with a dream, pick a body, and make it yours. But from where we stand — in the middle of a shop that’s built hundreds of them — it’s a lot more than nuts and bolts.

Building a car from the ground up is equal parts passion, patience, and precision. It’s the art of turning a vision into something that can idle, rev, and run. And it’s not cheap, not quick, and not for the faint of heart.

But when it’s done right, there’s nothing like it.

What “From Scratch” Really Means

“From scratch” can mean two things: either a brand-new body or a complete teardown of an existing car until nothing’s left but the shell. From there, every single part — every wire, bolt, and bracket — gets built, cleaned, repaired, or replaced.

Some people do it for sentimental reasons — the car was handed down, or they owned one just like it when they were young. Others do it for the creative control — to be part of designing something truly one-of-a-kind.

As Doug likes to say, “Every single build is different. It’s as individual as the person it’s built for.”

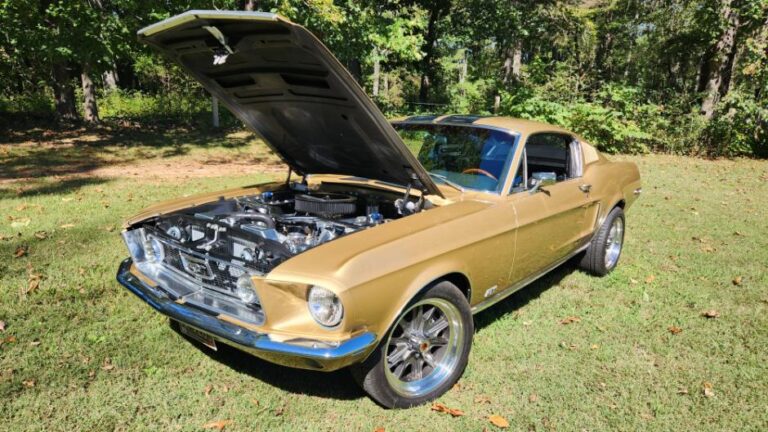

At Prestige, we’ve turned Cougars into GT500 hybrids, grafted fastback rear ends onto convertibles, and built cars you just don’t see every day. A restomod, a kit car, a full-on custom street rod — they’re all part of the same philosophy: bring the dream to life, no matter how wild.

How Much Does It Cost to Build a Custom Car?

Here’s where most people get caught off guard. It’s not the parts that kill you. It’s the hours.

A proper ground-up build takes around 1,000 hours. Multiply that by our shop rate — $150 an hour — and you’ve got $150,000 before we’ve even started adding parts.

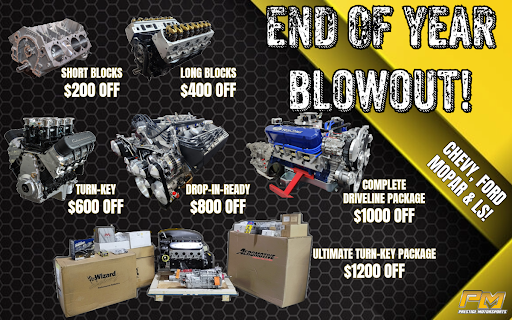

Now throw in a driveline package for around $50,000, plus suspension, interior, electronics, paint, and all the other details that make it a car and not a shell — that’s another $100,000 easy.

That puts most full builds around $300,000 when it’s done right. Some go higher, especially rare cars or heavy fabrication projects. Some partials come in lower.

Can you do it yourself? Sure. If you’ve got the equipment, the experience, and five years of weekends to spare. You might save $100,000 in labor — but you’ll give every penny of it back in time.

The Planning Phase — Where Reality Meets Vision

The first question we ask in any project is, “What’s your budget — and what’s liquid?”

That number drives everything. Some clients know exactly what they can spend. Others don’t, and that’s fine — we help them figure it out.

We use a Project Planner that breaks the job into phases: design, fabrication, assembly, and testing. It tracks hours, costs, and parts so you can see where every dollar’s going before we ever pick up a wrench.

Sometimes that plan means stretching a project over two years instead of one. Sometimes it means phasing it — getting the car running and roadworthy, then coming back later for paint, audio, or interior work.

And sometimes, it means saying no. Or at least, not yet. As Doug puts it, “If you want it done right and you care about details, we’ll have a great time. But if you want the most for the cheapest, it’ll never work.”

Renderings are another part of the planning phase that people underestimate. A detailed concept can run $30,000 to $40,000, but it keeps everyone aligned and can save five times that in the long run. It’s a roadmap — one that prevents the “how did we get here?” surprises later.

The Build Process, Step by Step

Every Prestige build follows the same pattern, refined over hundreds of projects.

1. Disassembly & Prep

We start by stripping the car completely, bagging and tagging every part, and replacing incorrect or damaged hardware as we go. Any rare or broken components get repaired on the spot. Once bare, the car goes through media blasting or a chemical dip, then an Ospho treatment to stop rust before it starts.

2. Fabrication & Fitment

This is where we correct body lines, align panels, and handle all the metalwork. If a car’s getting major changes — like a new roofline or custom brackets — it happens here. Every part gets mocked up, adjusted, and tested for perfect fit.

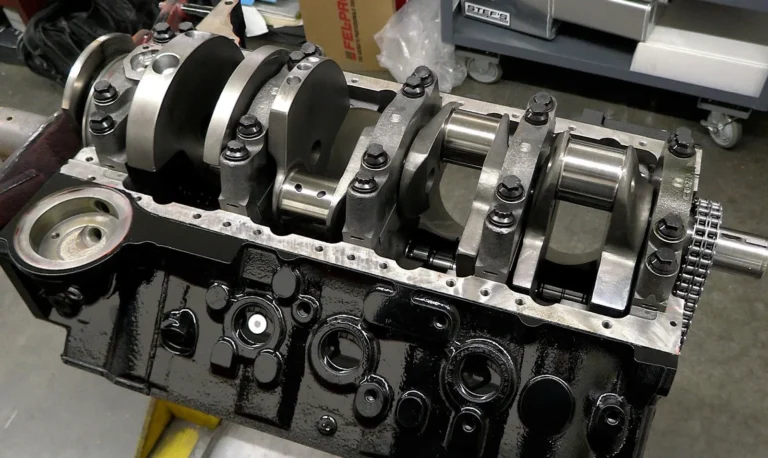

3. Rolling Chassis Test

Once the car is mocked up, we wire and assemble it just enough to run and drive unpainted. That means every system — cooling, electrical, drivetrain — is installed, connected, and tested.

We beat on it, find problems, and fix them. Customers even get to drive it at this stage.

As Doug says, “You don’t want to be grinding or welding on a $50,000 paint job. Spending $15,000 to test it first is cheap insurance.”

4. Paint, Assembly & Shake-Down

After testing, the car’s torn down again and sent to paint. When it comes back, it goes together like LEGO — everything fits, everything works. Before delivery, we put 250–500 miles on the car, checking every fluid, every bolt, every sound.

When you pick it up, it’s already been broken in and fine-tuned. No surprises. No shop dust. Just the car you dreamed about — finished and proven.

What Makes Some Custom Car Builds More Expensive (and Slower)

A few things always move the needle:

- Rarity. If we have to hand-make parts because they don’t exist, the hours add up fast.

- Materials. Fiberglass Corvettes, for example, must cure under UV light for months before paint.

- Engines. A turnkey crate might be $15K; a one-off powerhouse can hit $70K.

- Details. Adding AC, modern seats, or digital systems into a car that never had them means re-engineering half the interior.

That’s why we tell people a year is a realistic timeline for a proper custom build. Sometimes faster, sometimes longer. It depends on how far you want to go.

Transparency Is the Difference

A big part of what separates Prestige from the “guy in a garage” is transparency.

We send daily photos and video updates, paired with weekly billing, so you always know what’s being done, what’s next, and what it costs.

For remote clients, Doug sends WhatsApp video check-ins — short clips that show progress and ask for feedback in real time.

“It keeps them involved,” he says. “And it pumps them up for the next stage. When they see their car coming together, they’re excited to pay the next bill — not dreading it.”

No mystery invoices. No cars sitting untouched in the corner. Just communication, consistency, and craftsmanship.

Lessons from the Shop Floor

Doug’s advice for anyone considering a full custom build? Research.

“Go visit the highest-level shops you can think of,” he says. “You’ll see what quality looks like – and it’ll help you know what to expect. Just don’t go to a guy in a garage and hope for a miracle.”

Prestige’s approach is built on the same integrity and craftsmanship you’ll find in those shops, without the million-dollar entry point. If your dream and your budget align, they’ll bring it to life. If they don’t, they’ll help you phase it or pause it until the timing’s right.

What to Expect

At the end of the day, there’s no sugarcoating it:

Custom car builds are not cheap, and they always cost more than you think.

But when you see your vision come to life – when you hear it idle, smell the fuel, and feel it pull – it’s worth every penny.

Start Your Build with Prestige Motorsports

Every project starts the same way, with a conversation.

Whether it’s a phone call, a shop visit, or a video chat, we want to hear your ideas, your goals, and your vision. No pressure. No sales pitch. Just an honest talk about what it’ll take to make it happen.

Because at Prestige Motorsports, we don’t just build cars.

We build the ones you’ve been dreaming about your whole life.

Reach out to us to discuss your dream build today.